Multi-Etch Answers Customer Questions

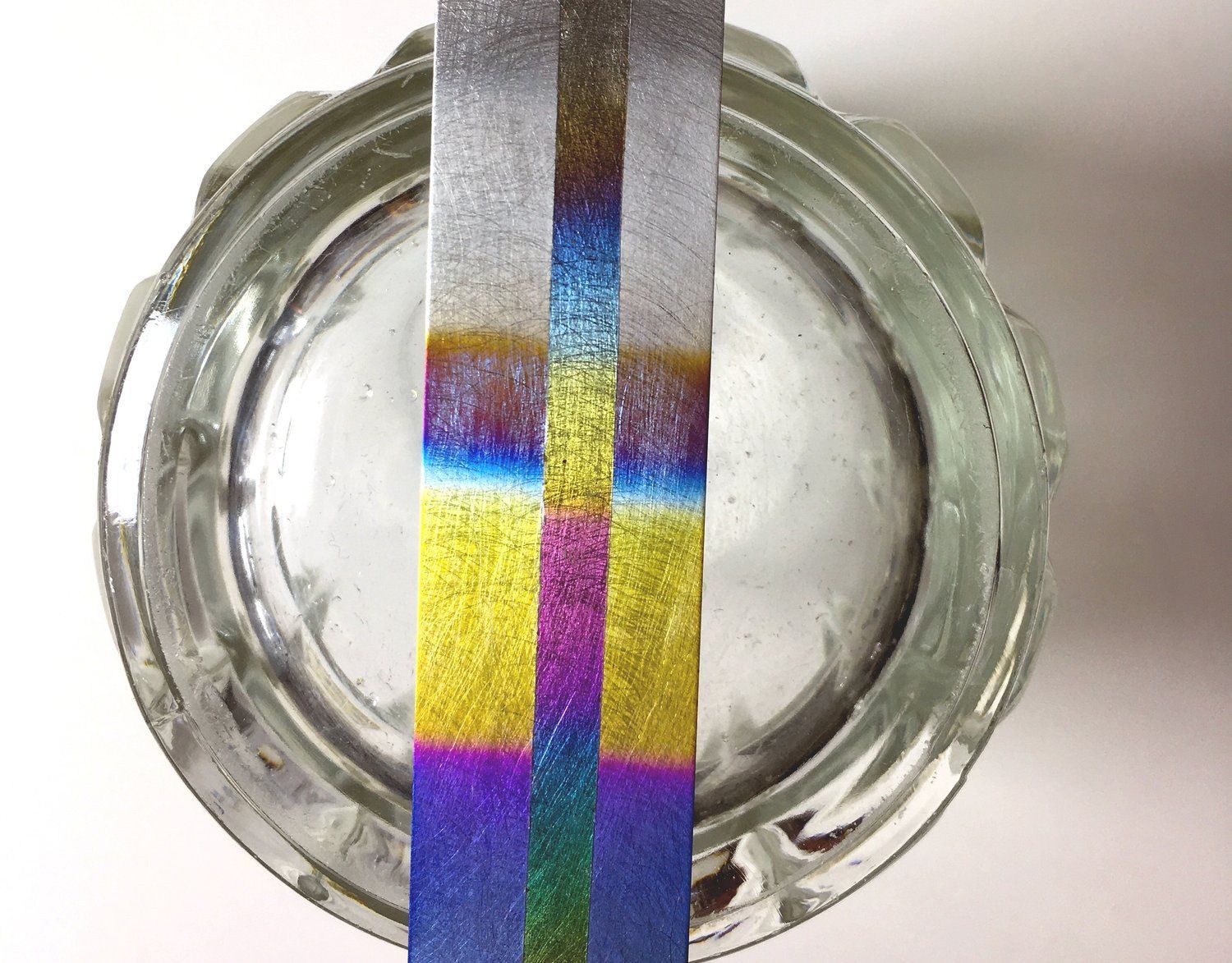

Copyright © Mark Fergus, used with permission

We have two subjects to cover: using Multi-Etch on different titanium alloys and reusing etch baths.

Question:

Will this product work on a titanium alloy? Not sure of the exact composition. When etching polished pieces, should the items be as close to polished already or will Multi-Etch affect the polished finish? What kind of depth will the etching do? Will I see difference in color on different titanium grades?

Answer

Multi-Etch will remove the oxide layer from all grades of titanium including alloys such as 6Al4V (generally known as 6/4 or grade 5) although we have not tested all of the alloys.

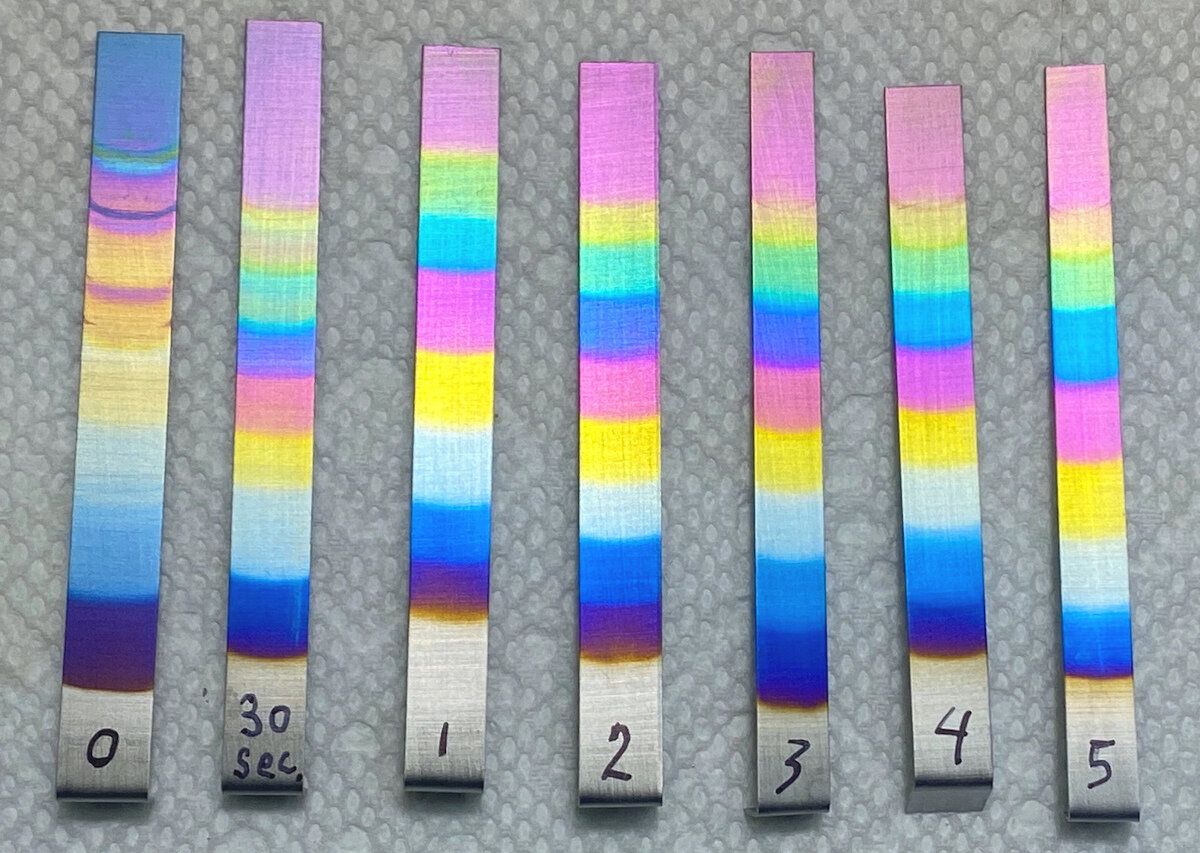

Do all your polishing/finishing, bead blasting, wire brushing, etc. prior to dipping in heated Multi-Etch. Adjust etch times for polished material as it will make the titanium matte if left in too long. Seven to ten seconds should be sufficient if you're etching to anodize. We've found that over three minutes will dull the polished finish. But if you left it in longer than three minutes, it will produce a satin finish, i.e., something between matte & polished. This all applies to heated Multi-Etch.

Check out our etch depth table . The longer you leave the titanium in Multi-Etch, the deeper the etch. Generally, for 6/4 titanium you can expect .0005" depth per 5 minutes in heated Multi-Etch.

There are a couple of alloys including 11 and 17 that have palladium in them. We haven't tested those but believe the etching will be slower because of the palladium.

You won't see any difference in the colors from grade to grade.

Question:

If I used my Multi-Etch one day, can I reuse it the next? Do you just place a lid on the solution? How long can it be exposed to air. Does the exposure to air affect its efficacy?

Answer

You can reuse the solution until it is no longer working for you. Put a lid on it to prevent evaporation but even if uncovered, it will not affect the efficacy. We have found the unused solution gets stronger after a couple of weeks or so. We have tested the unused solution up to a year after mixing it, and it still works fine. As always, it's best to pour out the smallest amount you need for a given job, keeping the rest of your solution uncontaminated. But then you can keep using what you poured out until it no longer works.

Have additional questions about Multi-Etch? Visit our Frequently Asked Questions or email us at info@multietch.com