Etching safety and environmental issues: An overview

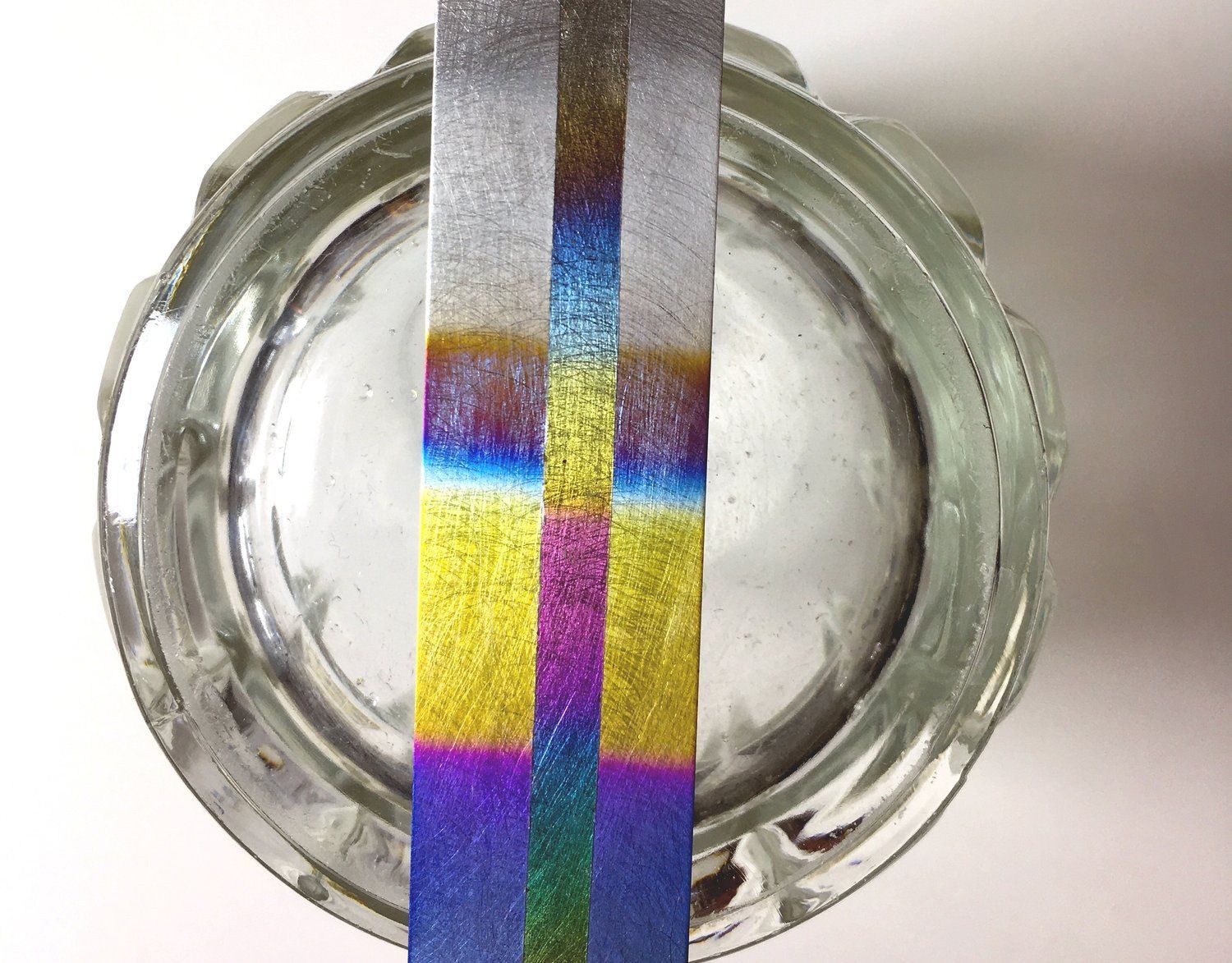

Titanium anodizing baths. Image courtesy IPEC Global.

We developed Multi-Etch in 1993 in order to use something safer than hydrofluoric acid to etch titanium. Although still considered hazardous, Multi-Etch has grown steadily for the last 15 years as the safer alternative. Not all uses of hydrofluoric have a safer alternative but using Multi-Etch to strip off the naturally-occuring oxide layer on titanium is a no-brainer.

This is one in a series of free online classes from IPEC Global about etching and anodizing titanium. The information is not new but is still very relevant. There are several more lessons on anodizing that are available free with an email .

By Mark Emilio, IPEC Global

I want to say from the outset that I consider titanium anodizing to be one of the most environmentally friendly and safest kinds of metal finishing or anodizing being done today. That said, depending upon which chemicals you choose, the potential risks to the environment and the safety of your employees are factors that you need to be aware of. You also have to understand that there are numerous options in the kinds of chemistry you can choose. This means that you can increase or decrease the risks of doing titanium anodizing by simply choosing the proper chemicals, equipment and procedures.

Environmental and safety concerns are not the same thing. They are regulated by different agencies and each has its own problems and solutions. When talking about environmental and safety issues, the best thing you can do for yourself is to be informed. And the worst thing you can do is to stick your head in the sand, ignore the regulations, and hope nobody finds out. IPEC Global has been doing this kind of work for the past 30 years and have learned that you can do this and do it well, but only if you decide to do it right. The trick is to be open and honest about your process so as to (hopefully) make the agencies love you and to learn about your process from you. If you need help, call us!

Environment

Environmental issues are concerned with what you dispose or emit into the environment and the community. This includes the air, water and ground. If you decide to use a particular chemical to etch titanium such as hydrofluoric acid, where will it end up after you are done using it? Will you discharge it to the drain and sewer? Or will you package it up and ship it to an approved landfill? Either of these options can be done legally, but which is more expensive in terms of money and manpower? Environmental guidelines and regulations come under the authority of such agencies as the US EPA. Most federal policies are enforced by state and local agencies. So it is probably your city, fire department and sewer district that will talk to you.

What kinds of environmental regulations must you comply with? Here are a few examples you can expect — there may be more or less depending upon your location, so be patient and flexible.

If you intend to discharge your rinse water down the drain, you will most likely be required to obtain an industrial wastewater discharge permit from your local sewer authority. In this case you will be allowed to discharge only those waters which meet specific standards of cleanliness, and you may have to use a wastewater treatment system to neutralize the water prior to discharge (see more on this at IPEC Global). On the other hand, if you choose to ship your wastes to a landfill, you will need an EPA generator ID number and a licensed hauler to transport the waste. If the process tanks emit a vapor, you may have to obtain an air pollution permit or officially request an exemption. Just do not be surprised if some bureaucrat from an agency you never heard of tells you have to fill out some forms and pay a fee.

Health and Safety

Safety issues are all about keeping people safe. For example, does the hydrofluoric acid you use to etch titanium pose a threat to you personally or your employees? What if it splashes into your eyes or burns your hands? And what kind of personal protection should you use, such as gloves, eye shields or aprons? My personal opinion is, whether you are using hazardous chemicals or not, it is always a good idea to use proper gloves and safety eye glasses. Safety guidelines and rules come from agencies such as OSHA and the Uniform Fire Code. Be ready to have your local fire department come in and inspect how you use and store your chemicals. As long as you have all of your records and can demonstrate that you are in compliance with their regulations, you should have few problems. If you are in the manufacturing business, you are probably already doing these things and titanium anodizing will not be a difficult addition to your existing programs. It just means that you have to do a little more homework.

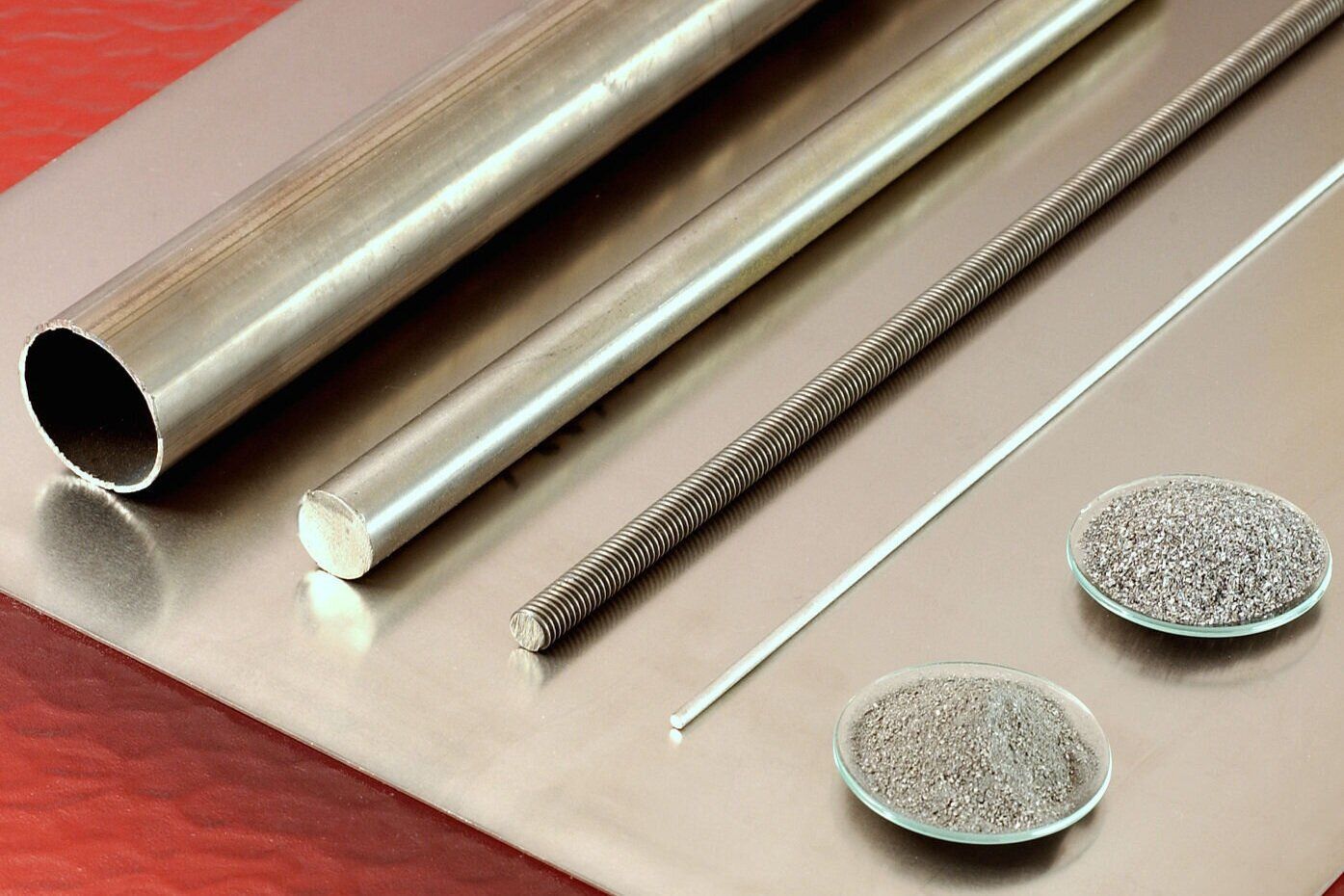

What specific chemicals are used in titanium anodizing? You have a number of choices, and it is here that the advantage of using a prototype system before committing to a large scale anodizing operation will become obvious.

Cleaners

You can use any one of a hundred water-based soaps that are non-hazardous if the parts are relatively clean before anodizing. Typical cleaning chemicals are TSP (tri-sodium phosphate), Dawn detergent and Simple Green for example. In some cases you may need to use a proprietary or high strength cleaner that contains sodium hydroxide. Sodium hydroxide is a hazardous chemical. It will have a high pH from 10&8211;14, (about 4%) and may be heated up to 180°F. At times where parts are coated with heavy grease or oils, some clients pre-clean their parts with Acetone before going into the cleaner. Where heated tanks are used, you will mostly have steam and elevated humidity in the room. As such, you may need an exhaust hood to remove the vapors.

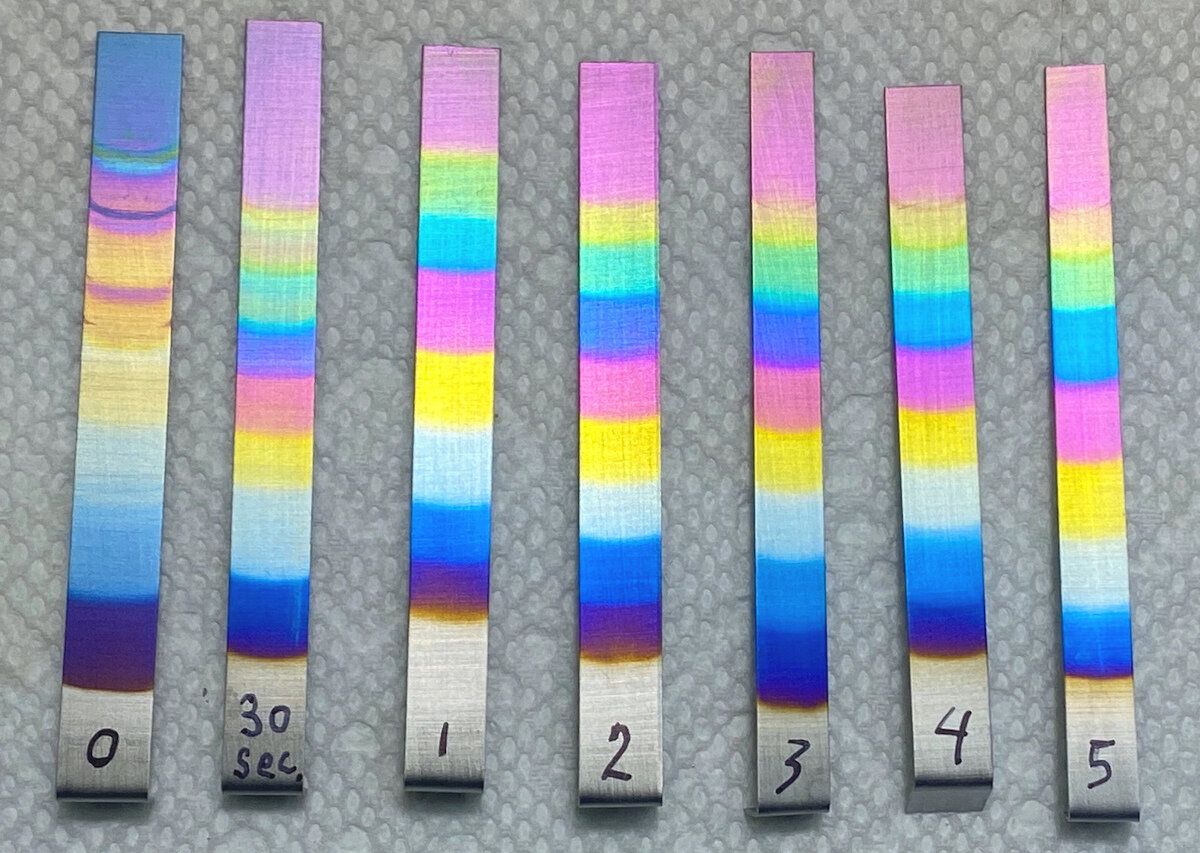

Titanium Etching

The chemicals necessary to etch titanium are usually hazardous. They must be treated with care and only by properly trained employees using the proper safety gear. Hydrofluoric acid, ammonium bifluoride, ammonium persulfate and nitric acid are common. There are also proprietary etchants available from vendors, and some of these etchants plus a couple of the "generic" recipes we provide with our systems are much easier to handle than hydrofluoric acid. Good ventilation is a must when dealing with any of the etchants.

🡆 Read: Hydrofluoric acid vs. Multi-Etch

Titanium Anodize Electrolytes

The electrolyte is the bath where the actual anodizing takes place. There are a number of anodize baths that you can use. Some are non-hazardous like sodium bicarbonate or trisodium phosphate. If you do not have a specification requirement forcing other chemistries (like a Mil-Spec), we suggest that you stick with these non-hazardous baths.

Many baths are room temperature. Titanium baths used in aerospace processes sometimes require high-alkaline electrolytes which contain sodium hydroxide and these are definitely hazardous. Typical baths used in medical device anodizing will normally be sodium bicarbonate with or without an additive. Many titanium anodize baths are "proprietary" or "trade secrets." But trade secrets many times involve the use of conventional chemicals, while the "secrets" are based to a large degree upon the concentration of the various chemicals and the procedures that are used in anodizing the parts. Selecting the right electrolyte is a matter of choice and experimentation. It may take a little time until you decide on the bath that is right for you and your products.

A note on electrolytes: The use of chemicals like sodium chloride or fluorides are not recommended for electrolytes. Remember that you will be applying a DC charge to the surface of the parts and in doing so you will create various gases based upon the makeup of the bath. With sodium bicarbonate you will create carbon dioxide, but with sodium chloride you will create chlorine gas. So do not experiment with electrolytes unless you do your homework!

To sum up, environmental and safety issues surrounding titanium anodizing are relatively mild when compared to other forms of anodizing and especially when compared to plating and most other metal finishing processes. You do have to do your homework and expect that you will need to train your people in the proper use of these chemicals. If you buy equipment, your vendor should be able to help train your people. You will also need to handle and dispose of your chemicals properly and within the guidelines of the various laws governing these chemicals. But when all is said and done, titanium anodizing is most definitely a "user-friendly" process.

-Mark Emilio

There are still companies that have been using HF for a long time and for those companies, we offer the following:

New protocols for using hydrofluoric acid (PDF) from Carnegie Mellon University's Hydrofluoric Acid Safety Program.